End Suction Fire Pumps

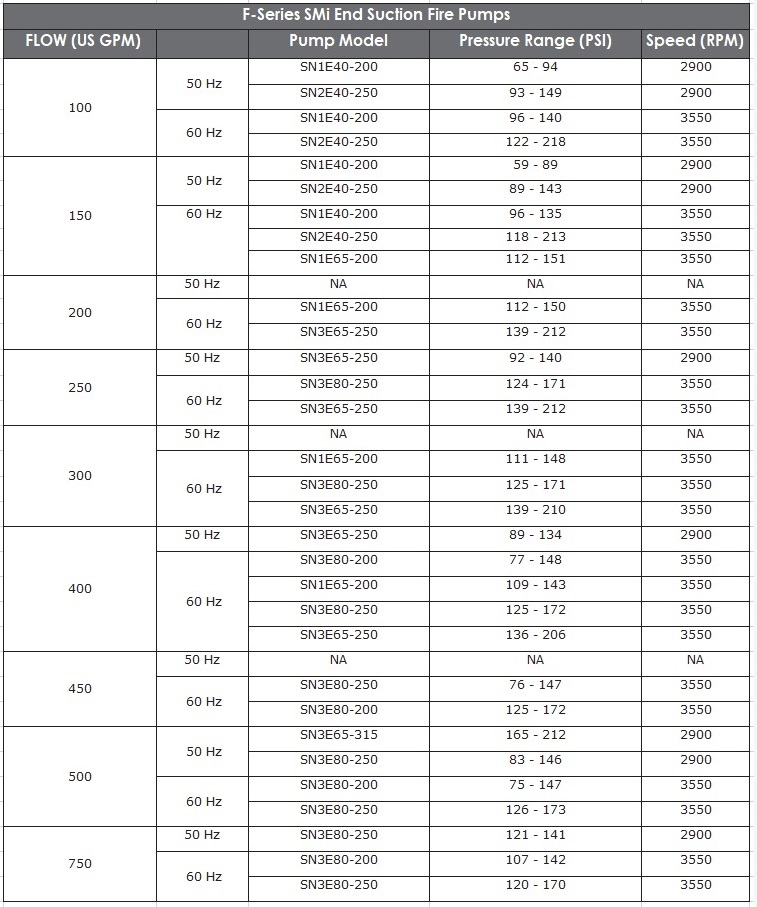

SMi is listed by Underwriters Laboratories (UL) for manufacturing end suction pump with flow range from 100 US GPM up to 750 US GPM. and a pressure more than 200 PSI.

PERFORMANCE RANGE

Design Features:

Ø

Pump Casing

The casing

is back pull-out design to allow pulling out the internal components (rotating

parts) for inspection and/or replacement without disturbing the pipe work. The

volute is made of fine- grain cast iron as per ASTM A48 specification equipped

with integrated support feet.

Ø

Impeller

Enclosed,

single suction type cast in one piece. The impeller is dynamically balanced to

ISO1940 and hydraulically balanced through the thrust holes on impeller

suction. The impeller is keyed to shaft and held in lateral position between

the sleeve and the nut.

Ø

Wearing Rings

The pump is

fitted with renewable type casing and impeller wearing rings to maintain proper

running clearance and to minimize the leakage between the suction and discharge

chambers.

Ø

Shaft Seal

TWINNER SYSTEM®

sealing is made of soft-packed stuffing box with graphite impregnated rings.

The gland is made of two halves that greatly facilitates the replacing

operation of the soft packing without the need to disassemble any component.

The stuffing box is fitted with lantern rings to improve the cooling and

lubrication of the shaft