At Deliverool, we are a leading provider of top-notch firefighting and water pumping solutions. With a strong presence in Egypt, Saudi Arabia, and Uganda, we are committed to empowering communities with cutting-edge equipment and technology to enhance safety and water supply. Our comprehensive range of services includes firefighting solutions such as fire pumps, fire suppressions, fire detection, and gas detection. Additionally, we offer an array of water pumping solutions, including pedestal pumps CS, vertical pumps CV, multistage pumps CM, and dual flow pumps CD. As a customer-centric company, we take pride in delivering the highest quality products and services tailored to meet the unique needs of our clients. With a focus on safety, innovation, and sustainability, Deliverool is your trusted partner in safeguarding lives and properties, as well as ensuring responsible water usage and conservation.

Emergency Call

01016000319

Emergency Call

01016000319

We saved 3800 + lives and protecting properties

Fire Fighting

Fire Pump

Fire Suppression

Fire Detection

Gas Detection

Water Pumping

Renetra - Pedestal Pumps CS

Horizontal, lever, radially split single-stage pump with axial inlet and radial impeller. Designed for removal of the rotor assembly with the bearing bracket without disrupting the flange connections of the suction and discharge flanges. Basic version is with closed impeller and grease lubrication. Seal chamber are designed for installation of compressed seals, mechanical seals, folded or cassette structures, including the installation of a double seal. ISO 5199, EU directive ATEX 2014/34/EU Technical specficationsQ max = 1700 m3/hH max = 140 mT max = 180 °C ApplicationThe pump is used in basic pumping applications for water, chemical or volatile media, demanding/heavy duty chemical and petrochemical plants and power plants. Pumping low-percentage suspensions, in the food industry and biofuel production. Suitable for high temperature media not exceeding 160 °C. ModificationSemi-open or open impellerOil lubricationCooled / heated seal chamberCooled / heated casing of the bearing consoleSeals according to API682 InducerPedestal pump CS2Horizontal, radially split single-stage pump with axial inlet and radial impeller. Cantilever design with pump in shaft axis. Designed for removal of the rotor assembly with the bearing bracket without disrupting the flange connections of the suction and discharge flanges. Pump design is in accordance with API 610-OH2. Bearings are lubricated with oil bath. Seal chambre is designed for the installation of mechanical cassette seals according to API 682. Bearing bracket is equipped with ribs for intensifying heat transfer. API 610/ISO 13709, ISO 5199, EU directive ATEX 2014/34/EU Technical specficationsQ max = 4500 m3/h (@ 50 Hz)H max = 360 m (@ 50 Hz)T max = 450 °C ApplicationPumps are used in the most demanding chemical and petrochemical plants and power plants. It is a typical pump for use in cracking systems. Designed for high temperature media up to 450 °C.ModificationAdditional fan/ventilator for the bearing consoleCooled / heated seal chamberCooled / heated casing of the bearing console InducerPedestal pump CS3Vertical, radially split pump with closed radial impeller. „IN-LINE“ design. Designed with bearing bracket or impeller shaft is directly connected to the electric motor shaft. The product line is manufactured with a standard impeller or dual-flow impeller concept. Grease lubrication. Seal chamber designed for installation of compressed seals, mechanical seals, folded or cassette structures, including the installation of a double seal. ISO 5199, EU directive ATEX 2014/34/EUTechnical specficationsQ max = 380 m3/hH max = 150 mT max = 120 °CApplicationThe pumps are used in plants with a complex layout due to minimal floor space. Closed cooling systems in power plants, remote heating, industrial water circulation, pumping water or mildly aggressive media and other media.ModificationBearing bracket designPump shaft connected directly to the motor Dual flow impeller

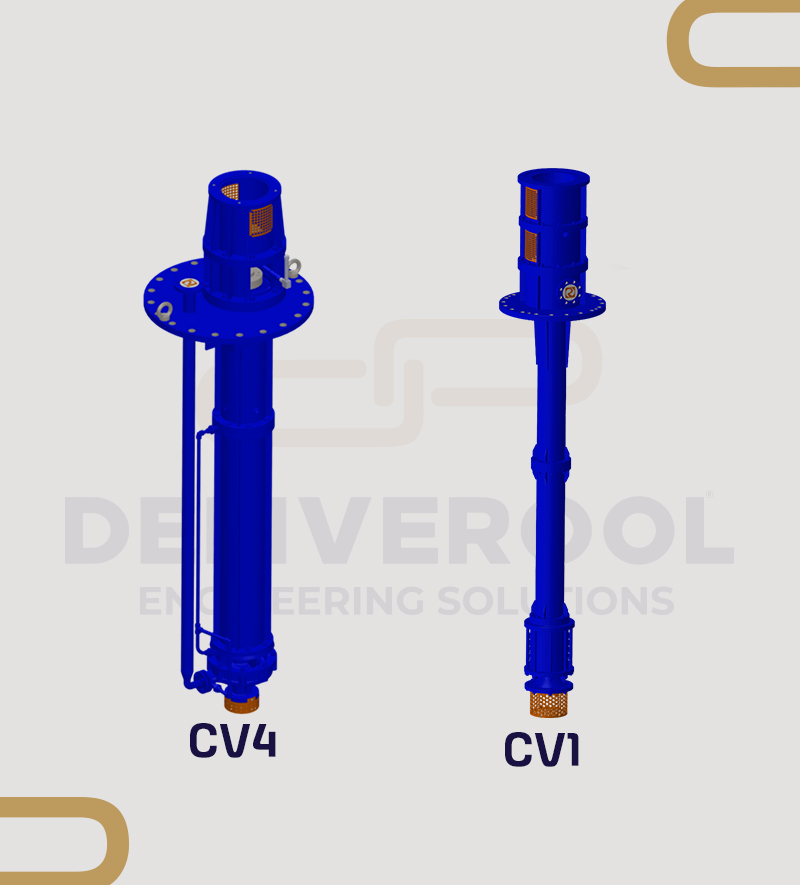

Renetra - Vertical pumps CV

Vertical pumps for wet sumps with a radial or diagonal impeller. Designed with a by-pass shaft or discharge casing from the spiral cabinet. Vertical pumps for wet sumps with a by-pass shaft. The product line is manufactured with a radial or diagonal impeller. One or more impellers. Pump bearings of small parameters are lubricated with grease. Pump bearings of large parameters are lubricated with oil. Seal chamber is designed for installation of a compressed seal. Guide shaft sleeves are lubricated with a pumped medium.Technical specfications Q max = 10 000 m3/hH max = 320 mT max = 210 °C ApplicationThe pumps are used for pumping process water, river water, utility and polluted waste water. Installed in water supply systems, cooling systems in power plants and industrial water circulation. Pumping water from deep sumps. The encased shaft and guide sleeves versions are used to pump water and suspensions with a higher content of solid particles. ModificationEncased shaft for external flushing / lubrication of guide sleevesCooled/heated oil filling of the bearing bracket Device to prevent reverse rotation of the machineVertical pump CV4Vertical, radially split single-stage pump with axial inlet and radial impeller for installation in wet sumps. Pump design is in accordance with API 610-VS4. Bearings are lubricated with grease. Seal chamber designed for the installation of mechanical cassette seals according to API 682. Guide shaft sleeves are lubricated with a pumped medium. API 610/ISO 13709, EU directive ATEX 2014/34/EU, ISO 5199 Technical specficationsQ max = 350 m3/hH max = 110 mT max = 150 °C ApplicationPump are used in chemical and petrochemical plants, power plants, as well as for transporting water and contaminated water. They are part of the installations in closed tanks or open sumps. Widely used in cracking systems, for pumping of the process residues and waste products. Used for pumping aggressive media. ModificationExternal flushing / lubrication of guide sleeves Heated structure

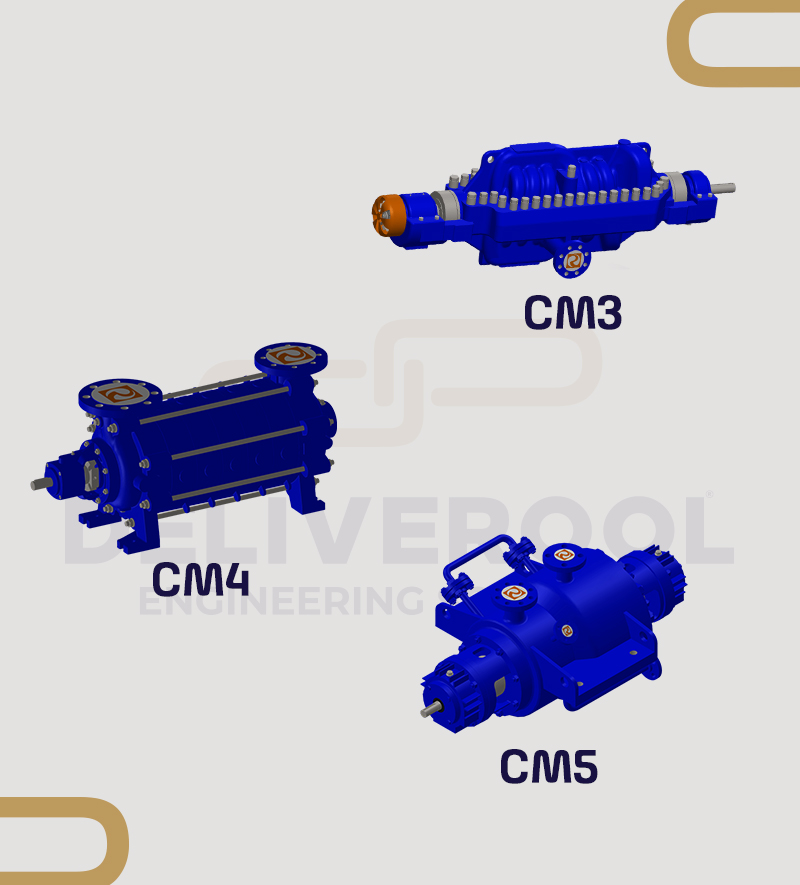

Renetra - Multistage pumps CM

Multistage pumps with radial impellers. Serial or mirror impeller position. Radially split, articulated and barrel design, or axially split pump bodies.Horizontal, axially split multistage pump with radial impellers. Between bearing version. Cantilever design with pump in shaft axis. Pump design is in accordance with API 610-BB3. Combination of bearings, sliding pan for radial reaction and compensating rolling bearing for capturing residual axial force, lubricated with oil bath. The position of the impellers on the rotor assembly reduces the resulting axial force to a minimum. Seal chamber is designed for the installation of mechanical cassette seals according to API 682. Bearing bracket is equipped with ribs for intensifying heat transfer.API 610/ISO 13709, EU directive ATEX 2014/34/EUTechnical specficationsQ max = 1680 m3/hH max = 1000 mT max = 200 °CApplicationPumps are used in demanding chemical and petrochemical plants and power plants. It is a typical pump found in systems for supplying and transporting petroleum products and in cracking systems. Used in power blocks as power pumps and as injection pumps for oil fields. Designed for high pressure systems, maximum transport height (head) up to 800 m. Suitable for media with temperatures up to 250 °C.ModificationAdditional fan/ventilator for the bearing consoleCooled / heated seal chamberCooled / heated casing of the bearing consoleExternal lubrication system

Renetra - Dual flow pumps CD

One or two stage horizontal radial pumps. With a dual-flow impeller design or a combination of two mirror radial impellers, or a dual-flow impeller and radial impeller. Radially and axially split spiral cabinet. Horizontal, axially split single-stage pump with a radial dual-flow impeller. Bearings lubricated with grease. Seal chamber designed for installation of compressed seals, mechanical seals, folded or cassette structures, including the installation of a double seal. ISO 5199, EU directive ATEX 2014/34/EUTechnical specficationsQ max = 7500 m3/hH max = 190 mT max = 80 °C ApplicationPumps are used in chemical and petrochemical plants and power plant’s cooling systems. Drinking and service water networks. Installations of fire systems and irrigation stations. Vertical design can be used to reduce space requirements. ModificationVertical design with one sealImpeller with overlapped blades Dual flow pump CD2Horizontal, radially split single-stage pump or two-stage pump with radial impeller. Between bearing version. Pump design is in accordance with API 610-BB2. Bearings are lubricated with oil bath. Seal chamber designed for the installation of mechanical cassette seals according to API 682. Bearing bracket are equipped with ribs for intensifying heat transfer.API 610/ISO 13709, EU directive ATEX 2014/34/EU Technical specficationsQ max = 1750 m3/hH max = 300 m T max = 450 °C